The UR-FREAK arrives as a technical anomaly, a watch that shouldn’t exist but does. This is the first time Ulysse Nardin has collaborated with a fellow watchmaking brand, and the pairing with URWERK produces something neither could have achieved alone. Limited to 100 pieces, the UR-FREAK replaces the traditional rotating gear train display of the Freak with URWERK’s wandering hours satellite system. The result demands close examination.

The Freak Legacy: Revolution in Silicon

When Rolf Schnyder unveiled the Freak at Baselworld 2001, traditionalists recoiled. No dial. No hands. No crown. The entire movement rotated to indicate time, whilst silicon components, a material previously reserved for computer microchips, replaced metal parts in the escapement. The concept originated with Carole Forestier-Kasapi, who won the Prix de la Fondation Abraham-Louis Breguet in 1997 with her vision of a revolving movement encased within a giant mainspring barrel.

Ludwig Oechslin transformed that vision into reality, collaborating with technical director Pierre Gygax to solve the considerable challenge of adapting semiconductor manufacturing technology for mechanical watchmaking. The original Freak featured a Dual Direct Escapement with silicon wheels, the industry’s first successful lubrication-free regulation system. Ulysse Nardin‘s confidence in silicon’s superiority was absolute: they positioned these novel components directly on the dial, exposing the innovation rather than concealing it beneath traditional aesthetics.

The company established Sigatec, its micromechanical laboratory, in 2006. By then, they had already introduced DIAMonSil in 2003, silicon coated with diamond to protect against the material’s inherent brittleness whilst maintaining its exceptional properties. Silicon offers decisive advantages: immunity to magnetic fields, resistance to temperature fluctuations, minimal friction requiring no traditional lubrication, and extended service intervals. Twenty-five years since introduction, only a few thousand Freak watches exist, yet the platform has accumulated over twenty patents and continuously advanced silicon technology that the rest of the industry now employs.

URWERK’s Satellite Genesis: Reimagining Time Display

Felix Baumgartner and Martin Frei founded URWERK in 1997 with explicit intentions. They refused to replicate existing complications. Their manifesto demanded original mechanical works that would expand, challenge, and transcend established horological boundaries. The brand name itself pays tribute to Ur, the Mesopotamian city where Sumerians first measured time through shadow-casting monuments, combined with the German “Werk” for mechanism. Together: original mechanism.

The satellite hour display emerged as URWERK‘s signature. The system used debuted not on a URWERK watch but on the Harry Winston Opus V in 2005, a landmark collaboration that established URWERK‘s technical credibility. The UR-103, launched at Baselworld 1997, introduced the minimalist wandering hour concept reminiscent of planets moving across the sky. Four orbiting satellites displayed hours, each rotating to present the correct numeral as it travelled across the minute track. This architectural, kinetic display language became URWERK‘s foundation.

Subsequent models refined the concept. The UR-202 added telescopic minute hands that adjusted length to follow minute track sectors via high-precision transporters. The UR-110, which earned the Grand Prix d’Horlogerie de Genève award for Best Design Watch in 2011, positioned hour satellites on a vertical carousel. Each iteration proved that time display could be sculptural, mechanical theatre rather than simple indication. URWERK maintains annual production at just 150 pieces, operating as a craftsman’s laboratory where radical design meets cutting-edge technology.

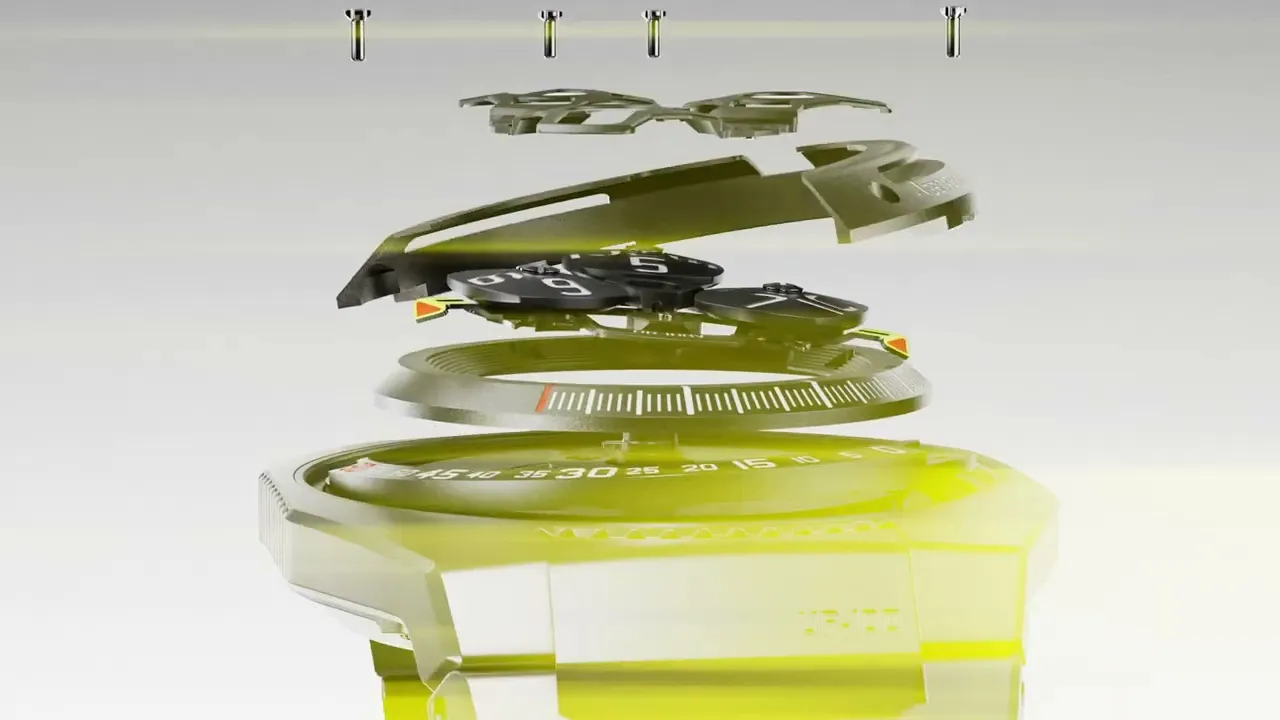

Satellite Theatre – A Full Scene Ballet

The UR-FREAK’s face abandons traditional dial conventions entirely. Time reads through three connected hands arranged in a rotating carousel that completes one full revolution every three hours. Each hand carries a domed disc functioning as a jumping hour display. The active hand slides along the minute indicator scale positioned on the right side of the face, URWERK‘s characteristic vertical minute track executed in electric yellow Pantone 395 C against sandblasted titanium.

The mechanism’s intelligence lies in the handoff. When the current hour completes its sixty-minute journey along the scale, the hour disc “jumps” to display the next hour. Simultaneously, the following hand positions itself at the zero mark of the minute track, ready to begin its traverse. This continuous three-hour cycle creates perpetual motion, with one satellite always actively indicating time whilst the other two prepare for their duty.

The layout provides immediate legibility despite mechanical complexity. Minute markers in yellow lacquer stand proud against the deep anthracite grey titanium base. The hour discs rotate beneath a large silicon balance wheel oscillator and escapement assembly positioned centrally, a departure from conventional movements where the regulator hides at the rear. Ulysse Nardin made this oscillator 25% larger than standard versions, possible only through advanced silicon fabrication. The oversized balance occupies the centre stage, turning with the satellite system in true carousel fashion. This constant orientation change serves a purpose beyond aesthetics: like a traditional tourbillon, the rotating assembly averages out positional timing errors.

The bridge carrying this mechanism receives ruthenium plating with yellow SuperLuminova accents that echo URWERK‘s signature colour scheme. Dial-side finishing includes Geneva stripes on visible bridges, circular graining on the base plate, and polished chamfers on component edges, “just” haute horlogerie finishing standards applied to an avant-garde display system.

Calibre UN-241: Integrated Architecture

The UR-FREAK houses the new in-house calibre UN-241, developed specifically for this collaboration. Based on the GPHG-winning UN-240 from the Freak ONE, the movement required developing over 150 entirely new components to accommodate URWERK‘s wandering hours satellite display whilst maintaining Ulysse Nardin‘s silicon technology advantages.

The movement’s construction defies conventional watchmaking sequences. Typically, movement and dial development proceed independently: function designed first, form applied afterward. The UN-241 demanded simultaneous conception of mechanics and display. The satellite system occupies substantial volume, whilst the oversized silicon oscillator required central positioning for maximum visual impact and efficient space utilisation. This integration necessitated rethinking gear train geometry, maintaining structural rigidity whilst accommodating the three-armed satellite carousel.

The silicon oscillator operates at 21,600 vibrations per hour (3 Hz), providing 90 hours of power reserve from a single barrel. The frequency choice represents deliberate engineering: lower than many contemporary movements but sufficient for excellent chronometric performance whilst extending power reserve and reducing component stress. The silicon balance wheel, hairspring, escapement wheel, and anchor require no lubrication and resist magnetic fields up to 1,000 gauss without rate deviation.

DIAMonSil technology appears in the escapement wheel and anchor, a critical components experiencing constant impulses. The diamond coating protects silicon’s crystalline structure from impact damage whilst maintaining the material’s low friction coefficient. This proprietary treatment belongs exclusively to Ulysse Nardin, developed through their Sigatec laboratory’s decade of silicon component research.

Movement finishing reaches manufacture standards throughout. Component edges show polished chamfers at precise 45-degree angles. Screw heads carry polished slots. The ruthenium plating on bridges provides both aesthetic contrast and surface hardness. Every visible surface receives appropriate treatment and nothing escapes attention despite the movement’s experimental nature.

The calibre measures 263 components assembled into 25 jewels. The gear train employs straight-toothed wheels with involute profiles for efficient power transmission. The satellite mechanism adds substantial complexity: three hour discs with jumping mechanisms, a rotating carousel with precise indexing, and the integration of this assembly with the traditional going train. The engineering challenge involves maintaining chronometric stability whilst a significant mass rotates continuously at the dial side. Weight distribution and moment of inertia calculations proved critical during development.

The silicon components themselves show extraordinary surface quality. Silicon machining through photolithography and deep reactive-ion etching produces geometries impossible in traditional metal components. The balance wheel spokes flow in organic curves optimised through finite element analysis for ideal mass distribution and rigidity. Surface smoothness reaches near-atomic precision: silicon wafer processing achieves nanometre-scale flatness, eliminating friction from surface irregularities that plague metal components even after polishing.

Grinder®: Winding Revolution

The UN-241 employs Ulysse Nardin‘s Grinder® automatic winding system, which represents the first genuine efficiency improvement to automatic winding in decades. Traditional automatic mechanisms require a certain volume of force and motion threshold before generating useful power – small movements produce insufficient rotor velocity to overcome the system’s inertia and friction losses. Grinder® converts even minimal wrist movements into kinetic energy through a blade-based oscillating system rather than a conventional unidirectional rotor. The blades catch the slightest motion, translating it immediately into winding action without requiring threshold velocity. The system consists of two oscillating weights connected through a gear train to the barrel ratchet. These weights operate at optimised mass and geometry to maximise energy capture across a wide range of motion amplitudes and frequencies. The practical result: the watch winds efficiently during sedentary activities where traditional automatic mechanisms remain dormant. Testing demonstrates Grinder® provides significantly higher winding performance during normal daily wear, maintaining power reserve levels that traditional rotors cannot match. The system also incorporates an automatic clutch mechanism that prevents overwinding: when the mainspring reaches full tension, the Grinder® system decouples automatically, allowing the weights to oscillate freely without stress on the barrel or gear train.

Case Engineering: Titanium Foundation

The UR-FREAK employs a 44mm case in grade 5 titanium, sandblasted to achieve deep anthracite grey finish characteristic of URWERK‘s aesthetic. The case architecture derives from the Ulysse Nardin Freak ONE, modified to incorporate URWERK‘s design language. Perceived height measures 12mm, a substantial presence on the wrist whilst remaining proportional to the diameter.

The bezel features three distinct fluted sections, a signature URWERK design element that adds mechanical sculpture to functional components. The fluting provides grip for bezel rotation, so the UR-FREAK, like all Freak watches, eliminates the traditional crown. A small “locker” tab at the six o’clock position secures the bezel during wear. Lifting this tab allows the bezel to rotate freely. This rotation doesn’t wind the watch but it adjusts the time by moving the hands. The bezel’s knurled surface ensures positive grip, whilst internal detents provide subtle indexing feedback during rotation.

The caseback, also in sandblasted titanium, features a sapphire window revealing the movement’s reverse side. Like the bezel, the caseback rotates, turning it manually winds the mainspring, necessary for the initial power-up before the Grinder® system engages during wear. This dual-control system maintains the Freak’s distinctive aesthetic purity: no crown interrupts the case profile, creating an unbroken circular form that emphasises the watch’s architectural qualities.

The titanium specification provides excellent strength-to-weight ratio. Grade 5 titanium (Ti 6Al-4V alloy) offers 30 per cent higher strength than stainless steel whilst weighing 43 per cent less. The sandblasted surface treatment creates uniform texture that disguises scratches and provides non-reflective finish. Yellow accents appear through anodised aluminium components. The locker tab carries “UR-FREAK” engraving, whilst the minute scale and hour disc numerals use yellow lacquer matching Pantone 395 C exactly.

Water resistance reaches 30 metres despite the rotating bezel and caseback complications. Gaskets seal the bezel and caseback interfaces, compressed when these components lock into position. Whilst 30 metres provides only splash resistance rather than swimming capability, achieving any water resistance with multiple rotating case components represents significant engineering, the sealing surfaces require precise tolerances and effective gasket compression across their entire circumference.

Strap Integration: Ballistic Rubber

Two strap options accompany the watch: integrated yellow rubber with “ballistic” texture, and an alternate black rubber variant. The yellow strap extends URWERK‘s Pantone 395 C colour signature from dial to wrist, creating visual continuity. The ballistic texture references tactical equipment aesthetics popular in contemporary watchmaking, executed through moulded surface pattern that improves grip and adds visual interest. The integration point uses Ulysse Nardin‘s proprietary attachment system: the strap flows directly from the case without visible lugs, creating unified architecture between case and bracelet. This integration demands precise manufacturing: the strap’s titanium core must match the case’s curvature exactly, whilst the rubber overmoulding must achieve consistent thickness and finish. A titanium deployant buckle, sandblasted to match the case, secures the strap with positive locking action.

Independence Realised

The UR-FREAK succeeds because it avoids cosmetic collaboration traps. This isn’t a dial repaint or case variant with co-branded signatures. The watch represents genuine technical collaboration: two manufacturers developing an entirely new calibre that integrates their respective specialties. URWERK brought satellite display expertise and design language. Ulysse Nardin contributed silicon component mastery and the Freak’s rotating carousel architecture. The result belongs equally to both whilst resembling neither’s existing catalogue exactly.

The collaboration proves that independent watchmakers can partner without compromising their identities. The UR-FREAK reads unmistakably as URWERK through its satellite mechanism, colour palette, and case finishing. Simultaneously, it carries Freak DNA through its case architecture, silicon technology, and time-setting methodology. Neither brand dominates but each contributes essential elements that create something genuinely novel.

For collectors, the UR-FREAK offers entry into two distinct horological philosophies simultaneously. URWERK’s 28-year history of reimagining time display converges with Ulysse Nardin‘s silicon revolution spanning 24 years. The piece carries technical significance: it proves that complex complications can merge without compromise when foundational engineering supports integration from conception rather than grafting systems together retrospectively.

The limitation to 100 pieces acknowledges the watch’s experimental nature whilst ensuring exclusivity. Production requires coordination between two manufacturers with different workflows, component specifications, and quality control standards. Each watch demands extensive hand assembly with the satellite mechanism’s precision tolerances leave no margin for component variance, whilst the silicon parts require specialised handling to prevent damage during assembly.

The UR-FREAK arrives at an interesting moment for independent watchmaking. As consolidation pressures increase and production costs escalate, collaborations offer independent manufacturers opportunities to share development costs whilst accessing complementary expertise. This watch demonstrates that such partnerships can produce technically significant results rather than merely marketing exercises. The horology community will judge the UR-FREAK not by its promotional materials but by its mechanical execution, and that execution proves formidable. Two companies that spent decades developing their respective specialties have merged those capabilities into a watch that neither could have created alone. That achievement deserves recognition.

URWERK X ULYSSE NARDIN UR-FREAK Technical Specifications

Reference: 2413-500LE-2A-UR/3B – €115.660, Production limited to 100 pieces

Movement:

- Calibre UN-241 Manufacture, automatic winding

- Functions: Hours, minutes via satellite display

- Construction: Flying carousel rotating around its axis

- Components: 263 parts, 25 jewels

- Frequency: 21,600 vph (3 Hz)

- Power Reserve: 90 hours

- Oscillator: Oversized balance wheel and hairspring in silicon

- Escapement: DIAMonSil wheel and anchor

- Winding: Grinder® automatic system with blade technology

- Finishing: Ruthenium plated bridges with yellow SuperLuminova

Case

- Material: Grade 5 titanium, sandblasted

- Case Diameter: 44mm

- Height: 12mm (perceived)

- Water Resistance: 30 metres

- Crystal: Sapphire front, sapphire caseback

- Crown: None—time setting via bezel, winding via caseback

Dial

- Satellite hour display with three rotating hands

- Display: Wandering hours with vertical minute scale

- Luminous Material: Yellow SuperLuminova

Strap & Buckle

- Strap: Integrated yellow or black rubber with ballistic texture

- Buckle: Titanium deployant, sandblasted