On Thursday, 7th of November, I was invited by Girard-Perregaux to visit their freshly refurbished manufacture. The tour was organised on three different brand’s sites: the manufacture at Rue des Crêtets, the Haute-Horlogerie Department at Rue Numa-Droz and, the final destination of the tour, the Girard-Perregaux villa. I will not be able to explain all the things that I saw but I hope it will offer you a glimpse of how things are done at the La Chaux-de-Fonds brand. The article will contain, in the end, some words about the new logo, the vision and the future of Girard-Perregaux. Image and video-heavy article.

Before going into more details, I invite you to have a look at the Girard-Perregaux history on their official Heritage & Duty webpage. A short crush introduction of this article can be seen in this 2017 official video below (available from the same webpage).

The joint manufacture at Rue des Crêtets

The manufacture tour started on the location at Rue des Crêtets. There, Girard-Perregaux and Ulysse Nardin share production spaces and lines. During the production, the spaces are well delimited between the brands. The same policy applies to the management and marketing departments, well defined and separated.

At the location, I was welcomed by Anna Lundstrom CMO of the Girard-Perregaux (communication and marketing) and Olivia Klay. The Rue des Crêtets serves as the production site for the brand’s core collection.

Where all starts

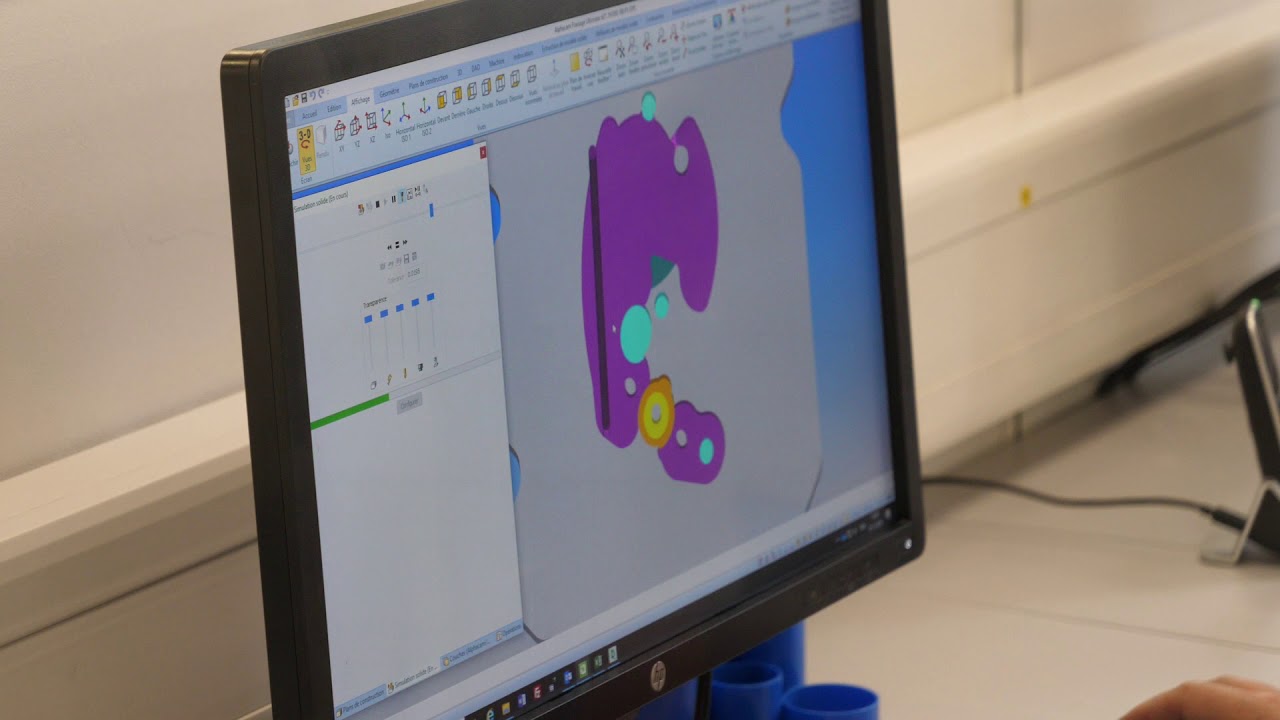

The first step in the creation of a new watch is the computer design. After the model is digitally created, simulated and tested, a prototype is manufactured. This one is tested in real-life situations but also in advance conditions. Only after a full working and reliable model is achieved, the new piece goes into production.

The R&D development team makes not only the digital design of new movements and cases. The production’s process is part of the R&D. Several tests are done to ensure the best quality in the new products: mechanical, thermal and even X-rays. The new materials for cases and movements are part of the investigations fulfilled by the R&D.

Gears and small parts

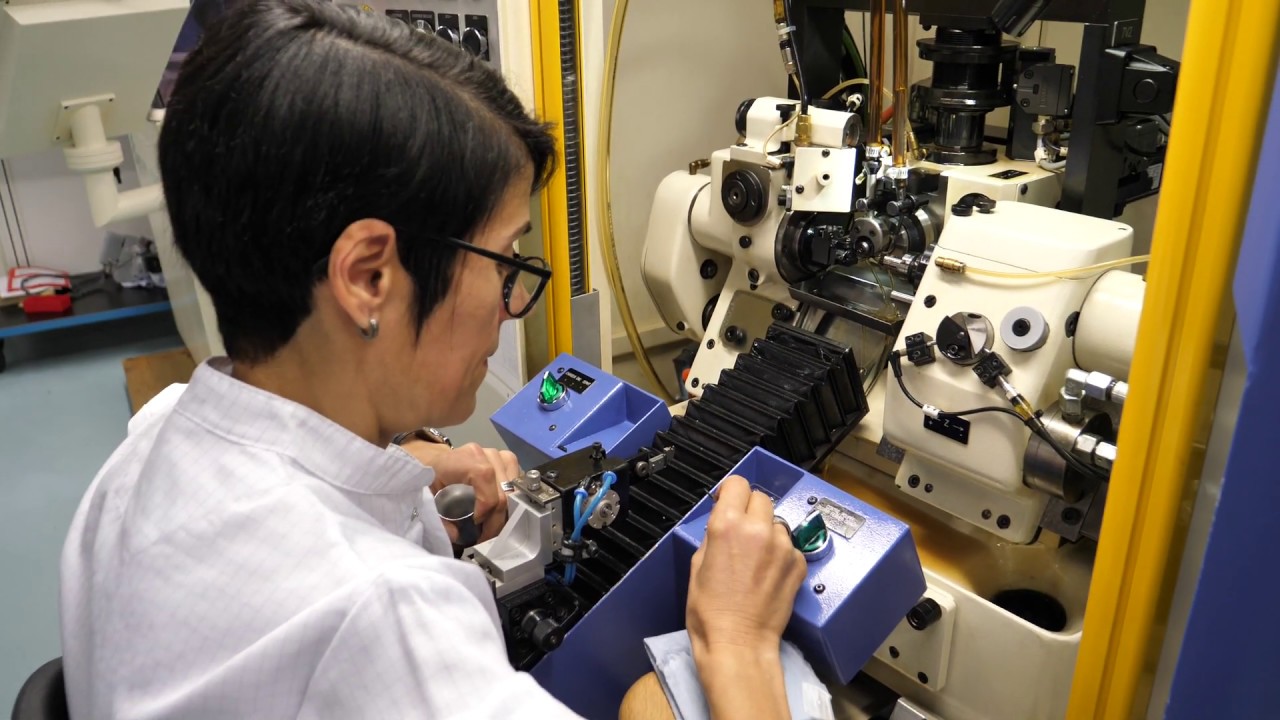

An entire room of the facility takes care of the production of small components – like the gears. In a room full of special machines, the gears and other round components are cut from metal roads. The raw pieces are then finished under the microscope.

When machines need human expertise

In the high-quality production, the final touch to a component is done by an experimented human hand. For example, these pins are machined produced and then rectified and checked by an expert.

Milling and CNC machines save a lot of time and produce high-quality components:

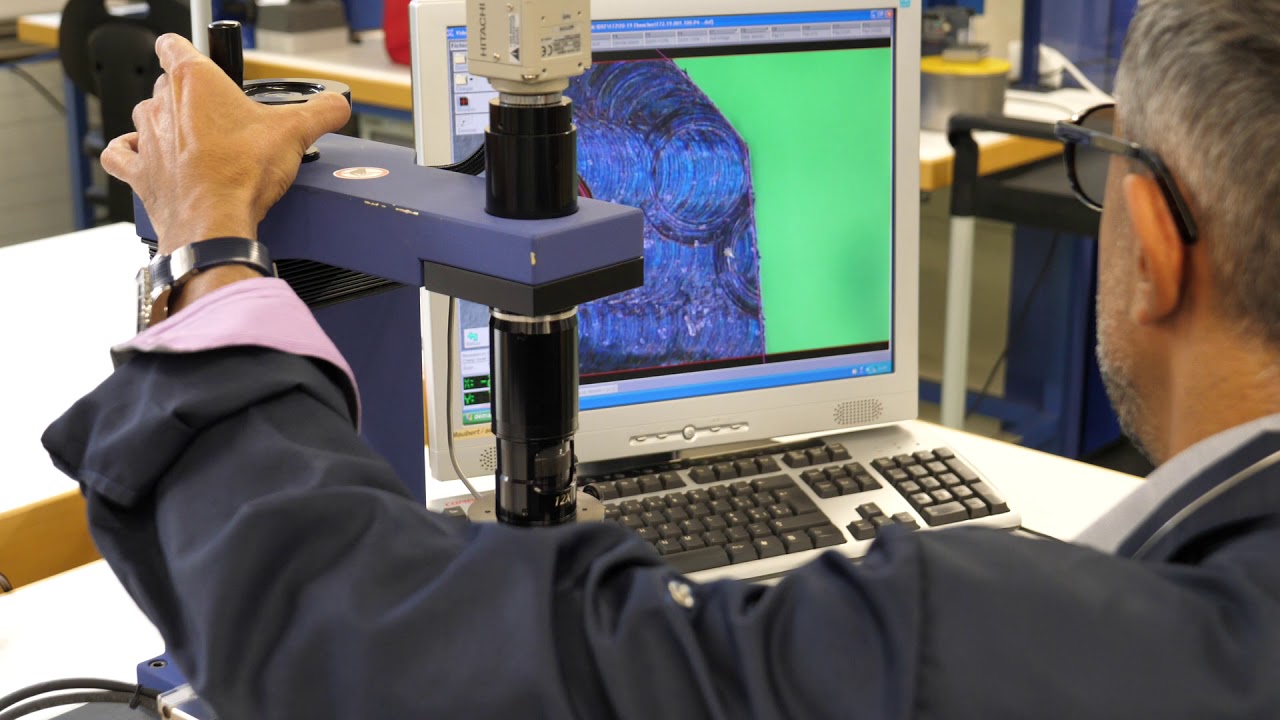

Checks & finishes before the final assembly

After the basic components are made, several operations must be fulfilled before going to be assembled. Some components need to receive and extra finishing step. Other need to be verified against the rigorous specifications.

Checking the milled parts:

Hand polishing for components:

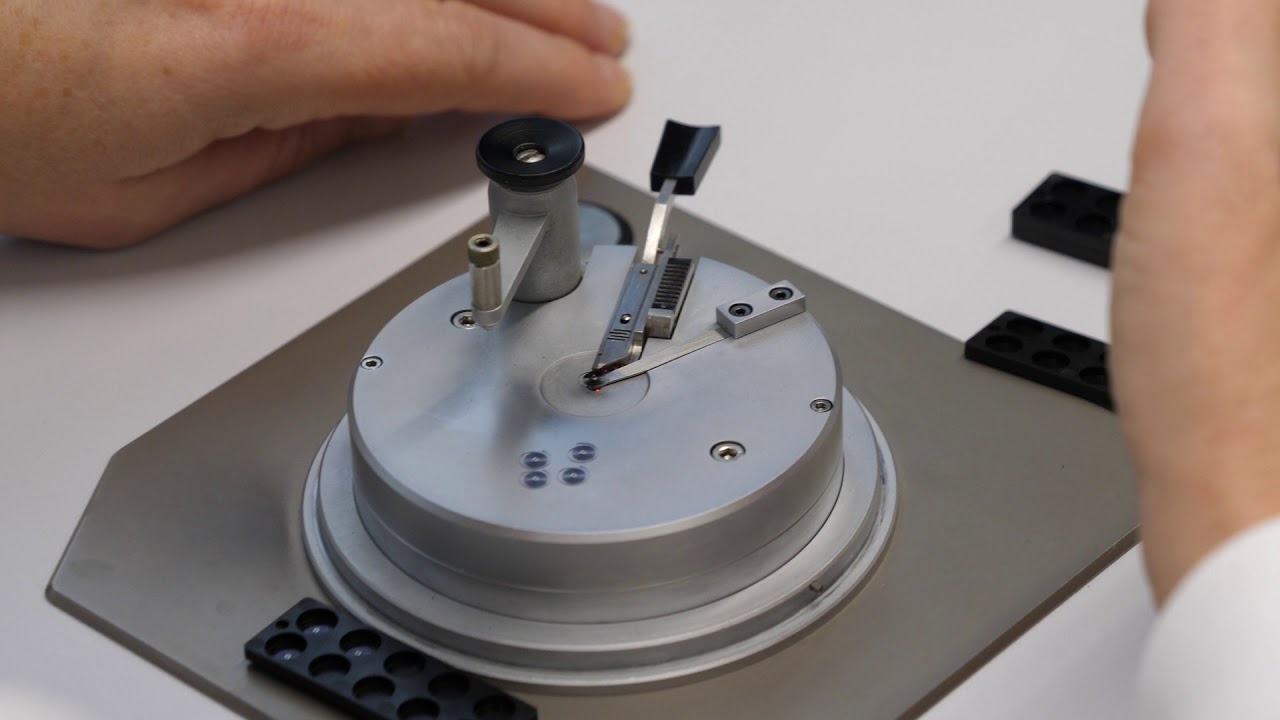

Spring tests:

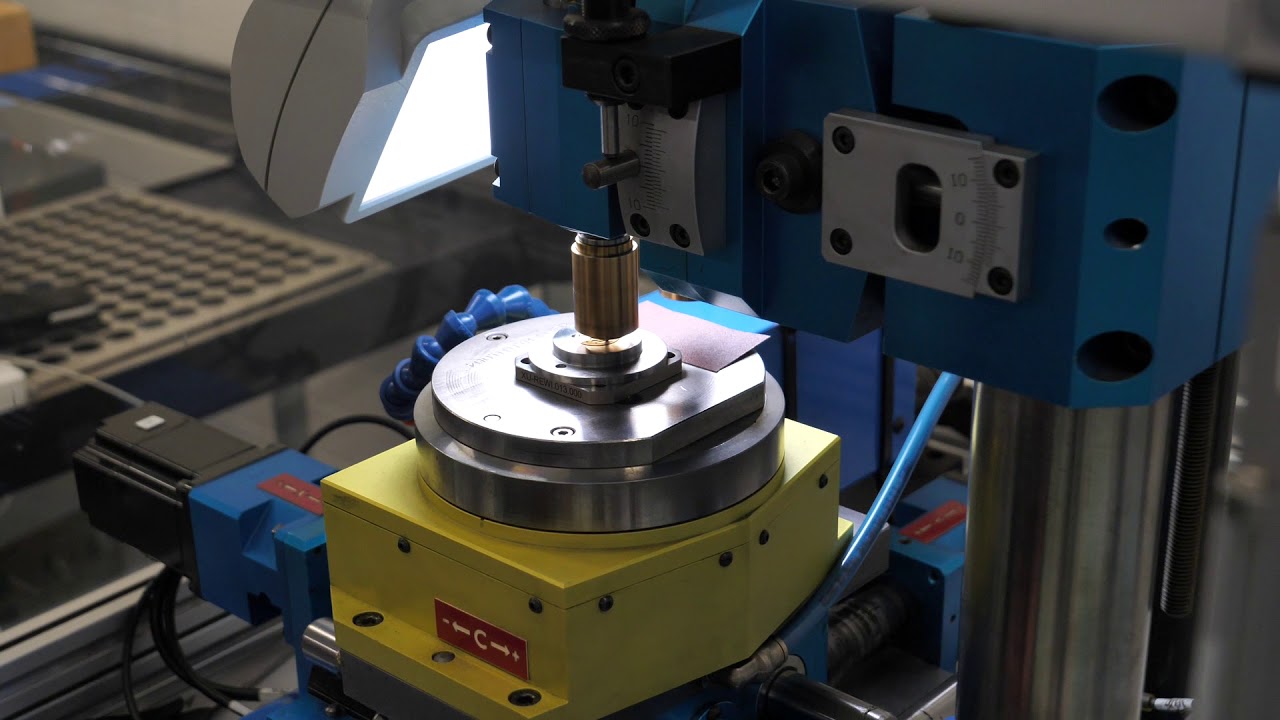

Balance wheel preparation:

Perlage: for some components, the perlage is realised using a specialised computerised machine. After decoration steps, all components go to electroplating (usually rhodium plating).

Automated processes

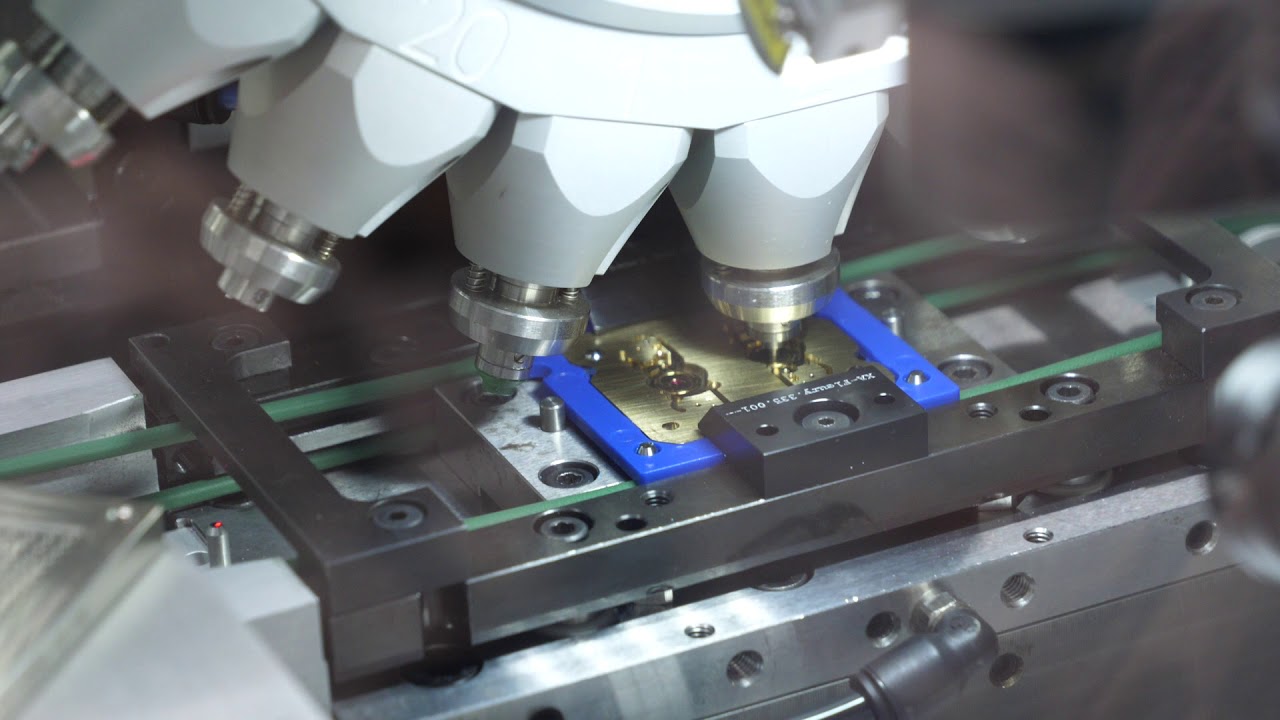

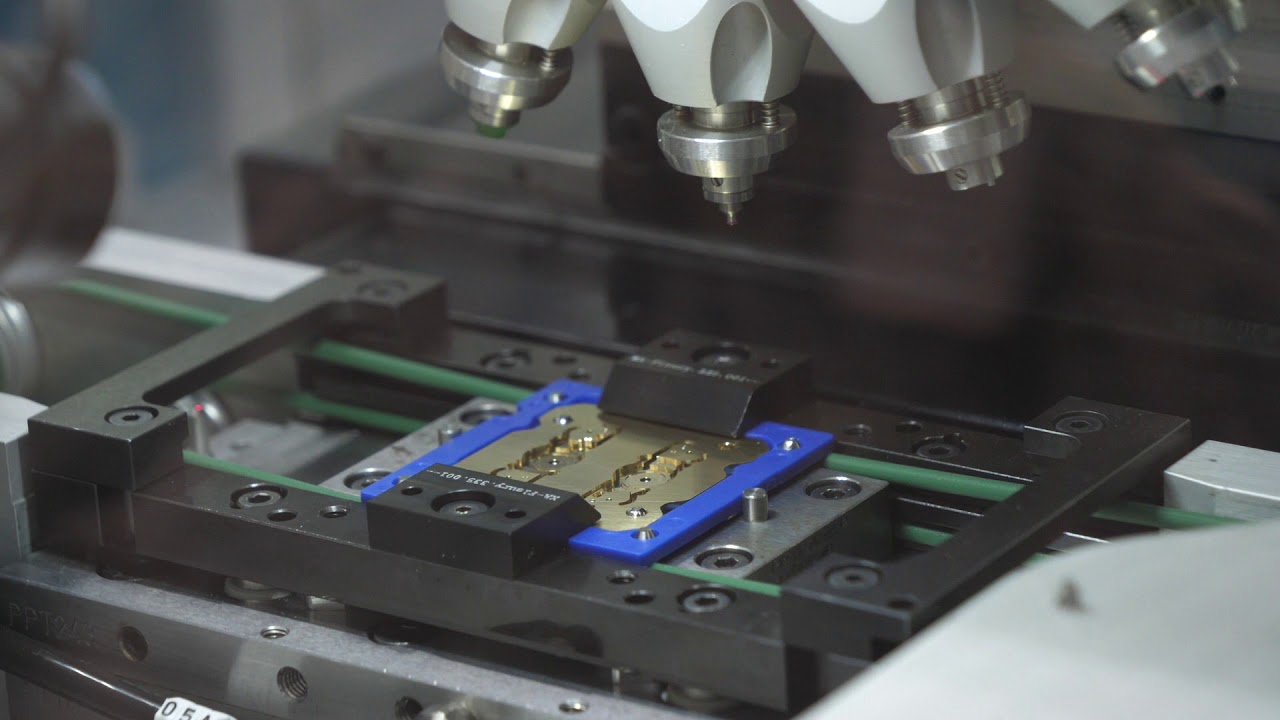

Some of the processes can be done fully automatic, like mounting the jewels in their sink. For that, a robot arm is used. This takes the jewels from a tray and precisely fit and press the jewels with micrometric precision.

Assembly line for movements and complete watches

The Girard-Perregaux assembly line is ultra-modern and combines the commodity of the machines with the knowledge and experience of the employees. The assembly lines use a robotic machine on which the movements are feed. The movements travel between the assembly stations and each watchmaker is doing its own steps. The movements that passed all the stations go further for hands mounting and encasing. Before being finally put in a case, all the movements are tested by a complex robot.

Testing the movements is a process that requires a lot of time. This time can be shortened by using a specialised robot that can test the movement using precise sensors. The chronometry is, in this way, fully automatic tested.

The hands of time the watch

One of the final operation done for a watch is attaching the hands. This are manually inserted. Some of the hands need to be manually bent to follow the top crystal curvature. The watchmaker does this operation with exceptional precision gained in the years of experience. The hands’ movement is tested between each step.

The Haute Horlogerie Department will be presented in the second part of the article.

Very interesting tour and great insights!

I would love to know if the cases and the dials are made in-house too, or if GP outsourced this?

More particular, I am interested to know if the anglage at the caliber 01800 is done by hand or by machines?

Thanks a lot, Alexander

´Hi Alexander,

I am glad you liked the article. Since I don’t remember all the details, I will ask GP.

I will come back to you with an answer.

Have a great day,

Andrei

Wow that is so kind, I can’t wait to know the response of GP. Thank you so much!

The case finish on the Laureato for example is quite complex and finely executed, however doing it equally well in ceramic, as they do, requires diamond coated tools. Not even to mention the new sapphire cases… I am curious.

As the GP 01800 in its basic version is not part of the high horology branch that you showed in part 2, I wonder if they also autmatised the rounding and polishing of the plates’ edges. I personally doubt it, as I think to remember seeing a super macro video of a 01800 where the anglage was varying in width to a slight degree. This should not happen with a robot executing and I thought it was a good sign.

Hi Alexander,

I have asked GP and the answers are:

– Not all cases and dial are made in-house. The ones externally made are in collaboration with local artisans, for instance, the full sapphire pieces like the Quasar (from the area around the Manufacture to a maximum of 100km away).

– As for movements though, these are always made in-house including all R&D – and this is why GP is a true Manufacture

– The chamfering is always done by hand at GP in general, not just on the 1800 calibre and is true of both external and internal angles.

My best regards,

Andrei