The new 50-piece limited-edition RM 21-02 Tourbillon Aerodyne in white Quartz TPT®, Carbon TPT® and titanium is the latest interpretation of an iconic calibre. A second iteration of the manual-winding tourbillon Calibre RM21-02, continues to redefine the boundaries of creativity through its harmonious fusion of precision, lightness and resilience.

Richard Mille has always capitalised on engineering materials from fields far afield from watchmaking, with the aeronautics industry exerting an especially strong influence. This never-ending source of inspiration is what brought a material with multiple properties to the brand’s Research and Development offices: Carbon TPT®️.

Used in aeronautics, but also greatly in the automotive industry (from plane fuselages to Formula 1 machines), Carbon TPT® is at the heart of the Richard Mille RM 21-02 Tourbillon Aerodyne baseplate. It is combined with a honeycombed structure produced of black-PVD treated HAYNES®️ 214®️, applied in the demanding environment of specialized gas turbine parts, such as honeycomb seals, combustor splash plates and other static oxidation-limited parts.

The alloy’s honeycombed geometrical pattern was originally the subject of research by NASA for applications on supersonic aircraft wings. Both materials definitely embody the concepts of air and speed.

Within this aerodynamic structure, the winding barrel and tourbillon are thoughtfully positioned centrally. They gracefully balance on lightweight titanium bridges with four arms on either side. Surrounding these components are torque and power-reserve indicators, providing insights into the quantity and quality of energy stored within the barrel. An added layer of control is also granted by the function selector.

The Richard Mille RM 21-02 case exhibits remarkable architectural intricacy, seamlessly associating Quartz TPT® and Carbon TPT® with a titanium caseband. This meticulous combination of materials yields a case that is not only visually captivating but also exceptionally robust, delivering unmatched resilience in the face of everyday use and its demands. This construction renders the RM 21-02 as one of the most sophisticated case constructions ever manufactured by Richard Mille.

Richard Mille, renowned for the brand’s unwavering dedication to innovation and the use of cutting-edge materials in watches has challenged itself once more to reimagine the unique specific aesthetic of the RM 21-02 Tourbillon Aerodyne.

Richard Mille RM 21-02 Tourbillon Aerodyne Technical Specifications

Limited edition of 50 pieces.

CALIBRE RM21-02: Manual winding tourbillon movement with hours, minutes, function selector, power-reserve and torque indicators.

Case dimensions: 42.68 x 50.12 x 14.30 mm

MAIN FEATURES

POWER RESERVE

Circa 70 hours (± 10%) indicated on the numeric scale at 11 o’clock.

BASEPLATE IN HONEYCOMBED ORTHORHOMBIC HAYNES®214® WITH CARBON TPT® CORE

HAYNES® 214® is a nickel-chromium-aluminium-iron alloy, designed to provide the optimum in high-temperature oxidation resistance for a wrought austenitic material, while at the same time allowing conventional forming and joining. Intended principally for use at temperatures of 955°C and above, 214® alloy exhibits resistance to oxidation that far exceeds that of virtually all conventional heat-resistant wrought alloys at these temperatures.

Combined with a Carbon TPT® core, the honeycombed geometrical pattern of HAYNES® 214® offers unparalleled stiffness, a low thermal expansion coefficient and exceptional torsion resistance. The orthorhombic baseplate is given a black PVD treatment to highlight its original construction.

BRIDGES MADE OF GRADE 5 TITANIUM

Bridges are crafted of grade 5 titanium, a biocompatible, highly corrosion-resistant and remarkably rigid alloy, which enables the gear train to function effortlessly. The alloy is 90% grade 5 titanium, 6% aluminium and 4% vanadium.

This combination further increases the material’s mechanical properties, which explains its frequent use in the aerospace, aeronautics and automotive industries. They are coated with black and grey PVD treatments.

FUNCTION SELECTOR

In a manner similar to a car’s gearbox, a push-button located at the centre of the crown allows one to select the winding, neutral and hand-setting functions with a simple push. A hand at 4 o’clock displays the selected function.

TORQUE INDICATOR

Utilising a numeric scale located between 12 and 1 o’clock, the indicator provides a visualisation of the mainspring’s internal tension, allowing optimisation of the movement’s timing. Below 5.3 N.mm, the spring is too slack; at the other extreme, above 6.5 N.mm excessive tension can adversely affect the running of the movement and may even cause damage.

FREE-SPRUNG BALANCE WITH VARIABLE INERTIA

The free-sprung balance offers greater reliability in the event of shocks or movement assembly and disassembly, and also guarantees better chronometric results over time.

FAST-ROTATING BARREL (6 hours per revolution instead of 7.5 hours)

This type of barrel provides the following advantages:

- The phenomenon of periodic internal mainspring adhesion is significantly diminished, thereby increasing performance.

- Provision of an excellent mainspring delta curve with an ideal power reserve/performance and regularity ratio.

BARREL PAWL WITH PROGRESSIVE RECOIL

This device permits an appreciable winding gain (circa 20%), especially during the start of winding. It also promotes the even distribution of the mainspring’s internal tension.

MODULAR TIME-SETTING MECHANISM ON THE CASEBACK

Provides the following advantages for longevity and maintenance:

- Since the component is mounted outside of the movement, the time-setting assembly can be changed without affecting the integrity of the baseplate in the event of a possible defect or during maintenance.

- The mounting and dismantling of this module from the back does not require the removal of the hands or dial.

WHEEL-BASED TIME-SETTING SYSTEM (BACK OF THE MOVEMENT)

Provides smooth time-setting functions by eliminating engaging friction and replacing it with rolling friction.

WINDING-BARREL TEETH AND THIRD-WHEEL PINION WITH CENTRAL INVOLUTE PROFILE

The central involute profile of the winding barrel teeth and pinion provides an optimal pressure angle of 20°. This promotes effective rotary motion and compensates for possible variations in the engagement of the going train, thus insuring excellent torque transmission with a distinct improvement in performance.

SPLINE SCREWS IN GRADE 5 TITANIUM FOR THE BRIDGES AND CASE

This permits better control of the torque applied to screws during assembly. These screws are unaffected by physical manipulation during assembly or disassembly and age well.

OTHER FEATURES

- Movement dimensions: 30.20 x 29.20 mm

- Thickness: 7.14 mm

- Tourbillon diameter: 12.30 mm

- Balance wheel diameter: 10.00 mm

- Jewels: 27, set in white gold chatons

- Balance: GLUCYDUR®, 2 arms, 4 setting screws, moment of inertia 10 mg•cm2, angle of lift 53º

- Frequency: 21,600 vph (3 Hz)

- Balance spring: elinvar by Nivarox®

- Torque indicator: with reference measurement in N.mm

- Shock protection: KIF Elastor KE 160 B28

- Barrel shaft: nickel-free Chronifer® (DIN x 46 Cr 13 + S) with the following characteristics: stainless – antimagnetic – suitable for tempering

CASE MADE OF QUARTZ TPT®, CARBON TPT® AND TITANIUM

From the case and dial to each piece of the movement, the design and execution of the watch demonstrate a holistic approach to conception of the movement, case and dial.

As a result, everything has been constructed according to extremely rigorous specifications. The casing ring is eliminated, and the movement is fixed to the chassis with four grade 5 titanium screws and silent blocks (ISO SW).

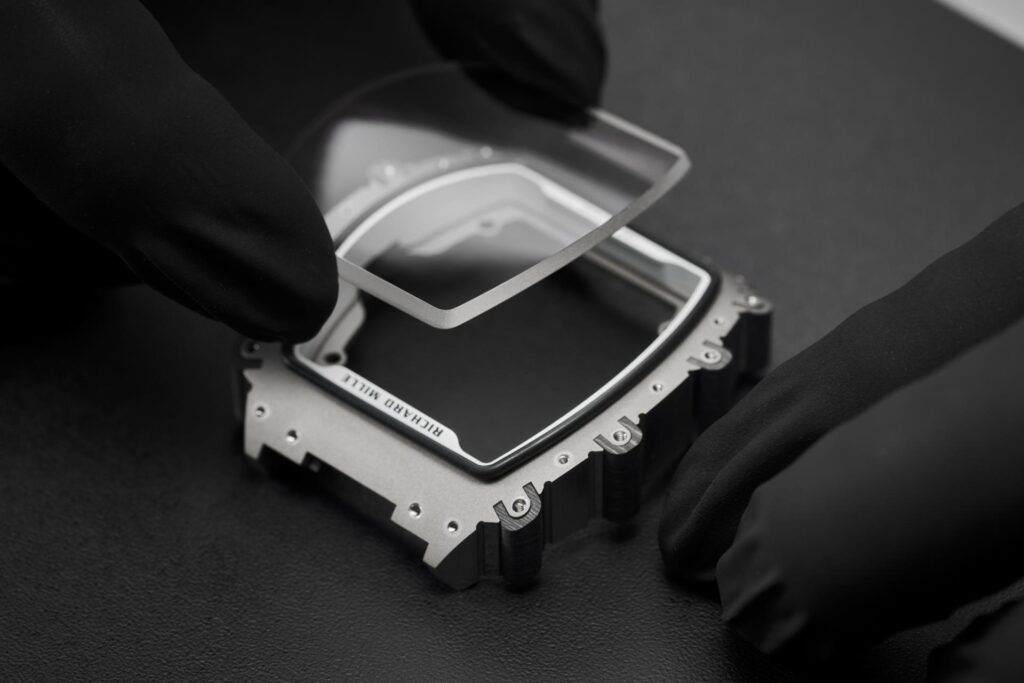

The bezel is made of Carbon TPT® and Quartz TPT®, two exclusive materials with unique appearances. Their remarkable surfaces display extremely regular undulations, as they are composed of multiple layers of parallel filaments obtained by dividing carbon fiber or silica threads. These layers, with a maximum thickness of 45 microns, are impregnated with matrices then woven on a special machine that modifies the direction of the weft by 45° between layers. Heated to 120°C at a pressure of 6 bars, these materials are then ready to be processed on a CNC machine in Richard Mille’s case factory.

Quartz TPT® is also used for the caseback while the caseband is made of satin-finished grade 5 titanium with pillars in Carbon TPT®.

The tripartite case is water resistant to 50 metres, ensured by 2 Nitrile O-ring seals. The case is assembled with 20 spline screws in grade 5 titanium and abrasion-resistant washers in 316L stainless steel.

INTERIOR FLANGE

In microblasted and satin-finished titanium with black galvanic treatment.

DIAL

In sapphire (thickness: 0.40 mm) with anti-glare treatment (both sides), protected by 8 silicon braces inserted in the upper and lower flanges grooves.

CRYSTAL

Bezel side:

In sapphire (1,800 Vickers) with anti-glare treatment (both sides).

Thickness: 1.50 mm

Caseback:

In sapphire with anti-glare treatment (both sides).

Thickness: 1.20 mm at the centre; outer edges 2.04 mm

FINISHING

MOVEMENT

- Hand-polished anglage

- Hand-polished locking sections

- Sapphire-blasted milled sections

- Lapped and polished contact points

- Burnished pivots

STEEL PARTS

- Sapphire-blasted surfaces

- Hand-polished anglage

WHEELS

- Concave chamfering with a diamond tool

- Circular-finished faces

- Rhodium plating (before cutting the teeth)

- Minimal corrections applied to the wheels in order to preserve geometry and performance