Richard Mille is proud to have always counted high-level sportsmen and women among the brand’s partners. As members of our large family, they are at the heart of developments that seek to continually roll back the limits of the feasible. To celebrate the release of our first women’s sports watch, the RM 07-04 Automatic Sport, Richard Mille asked six inspiring and influential athletes (Aurora Straus, Margot Laffite, Nelly Korda, Nafi Thiam, Yuliya Levchenko and Ester Ledecká) to share their experiences and develop and define the attributes of this watch.

•The first women’s sports watch in the collection

•Only 36 grams, strap included

•6 versions available

Two motorsport icons, the world number two golfer, two track and field stars, and a Winter Olympics triple gold medallist are the Richard Mille partners who proudly wear the six models in the new RM 07-04 Automatic Sport collection. Perfectly adapted to the constraints of their various disciplines, the timepiece asserts pure performance and technical sophistication simultaneously.

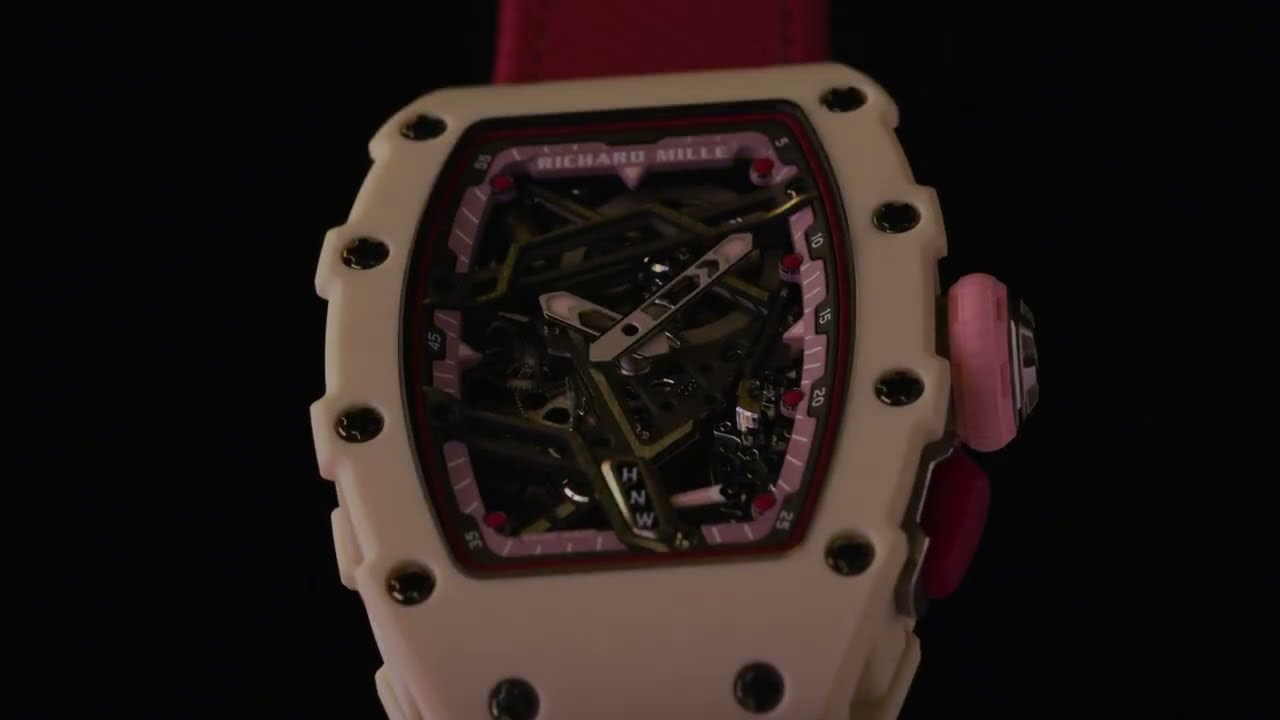

The creation of the RM 07-04 Automatic Sport required three years of development because there were so many challenges: developing a new, very compact and skeletonised in-house automatic movement, guaranteeing high shock resistance, integrating the exterior perfectly into the movement while leaving its workings visible… “We did not take a minimalist approach in this design, we chose an airy movement that revealed its complexity at first glance. Offering a women’s skeleton sports watch is a gamble that few have dared to take. This collection is as much about aesthetics as it is about technicity,” explains Cécile Guenat, Creative and Development Director at Richard Mille.

The Richard Mille CRMA8 calibre is a new in-house automatic movement with hours, minutes and a function selector. To ensure the rigidity of the assembly, the baseplate and bridges are made of grade 5 titanium, supplemented by a black PVD treatment. To earn its sports credentials, the movement underwent a series of rigorous tests to confirm its resistance to 5,000 g’s of acceleration, a major feat for the most compact of all the calibres developed by Richard Mille. Hand finishing that includes polished angles, milled sections, micro-blasted sinks and satin-finished surfaces enhance the elegance of its uncompromising mechanics. The compactness of the calibre further accentuates the quality of the production, as it renders the assembly stage considerably more complex for the watchmaker, for whom there is not the slightest margin for error.

The function selector complication, emblematic of the brand, prevents stress on the winding stem. Combined with a Quartz TPT® pusher at 4 o’clock, a simple press allows the user to choose between the neutral (N), winding (W) or time setting (H) positions. Its kinematics also are perfectly visible because its assembly is inverted compared to the brand’s other selectors. The hand at 5 o’clock indicates the chosen function on a flange in grade 5 titanium. A part as finely worked as those of the movement, this crucial element in the architectural aesthetics of the piece brings balance to the whole and contributes to the symbiosis between movement and decoration. Depending on the version, the case is crafted of Quartz TPT® or Carbon TPT®. Characteristically for Richard Mille sports watches, the colour combinations of these ultra-durable technical composites exude energy, strength and emotion.

The identity of this collection, imbued with a thirst for sporting achievements and the euphoria of competition, is revealed through its colour palette. The colours, from black for the Carbon TPT® model to cream white, mauve, salmon pink, green or dark blue for the five Quartz TPT® pieces, do not in any way alter the intrinsic characteristics of these materials, namely their lightness, their non-allergenic properties, and their resistance to shocks, UV rays or wear.

Assertive in every way – ergonomically, visually, technically and in terms of its performance – each watch in this collection is as pleasant to wear on a daily basis as it is suited to intense sporting activity.

Lightweight – at 36 grams including its Velcro® strap – the new RM 07-04 Automatic Sport collection offers athletes the freedom to be at their very best in their disciplines. This collection of six watches symbolises perfect versatility and continuity in the growing world of women’s watches at Richard Mille, a world where elegance and refinement are combined with ultra-high performance and sporting prowess.

Richard Mille RM 07-04 Automatic Sport Technical Specifications

Calibre CRMA8: Skeletonised automatic winding movement with hours, minutes and function selector.

Case dimensions: 30.50 x 44.95 x 10.35 mm

MAIN FEATURES

POWER RESERVE

Around 50 hours (± 10%)

BASEPLATE AND BRIDGES MADE OF GRADE 5 TITANIUM

Manufacturing these components in grade 5 titanium with black PVD and electroplasma treatments confers great rigidity on the entire assembly, as well as precise surface flatness, essential for perfect functioning of the gear train. Grade 5 titanium is a biocompatible, highly corrosion-resistant and remarkably rigid alloy, which enables the gear train to function effortlessly. The alloy is 90% grade 5 titanium, 6% aluminium and 4% vanadium.

This combination further increases the material’s mechanical properties, which explains its frequent use in the aerospace, aeronautics and automotive industries.

These components are satin-finished, microblasted and beveled by hand. They were subjected to separate and extensive validation tests to ensure they met rigorous strength requirements.

FUNCTION SELECTOR

In a manner similar to a car’s gearbox, a push-button located at 4 o’clock allows one to select the winding, neutral and hand-setting functions with a simple push. A hand at 5 o’clock displays the selected function.

FREE-SPRUNG BALANCE WITH VARIABLE INERTIA

This type of balance wheel represents the ultimate in innova¬tion. It guarantees greater reliability when subjected to shocks and during movement assembly or disassembly, hence better chronometric results over time.

The regulator index is eliminated, and a more accurate and repeatable calibration is possible thanks to 4 adjustable small weights located directly on the balance.

ROTOR IN PLATINUM

By using a platinum rotor with the OneWay® winding system and ceramic ball bearings, the barrel can be efficiently wound while maintaining the compact dimensions of the skeletonised movement.

FAST-ROTATING BARREL (5 hours per revolution instead of 7.5 hours)

This type of barrel provides the following advantages:

The phenomenon of periodic internal mainspring adhesion is significantly diminished, thereby increasing performance

Provision of an excellent mainspring delta curve with an ideal power reserve/performance and regularity ratio.

GEAR TEETH PROFILE

The entire going train of the watch, the primary transmitter of power throughout the movement, utilises a special profile for the teeth of the wheels, ensuring a 20° pressure angle. This system equalises any discrepancies that might arise among the centres of the wheels, for instance due to thermal changes and normal use, and promotes the smooth transmission of torque to the balance wheel, thus supporting excellent chronometric results.

SPLINE SCREWS IN GRADE 5 TITANIUM FOR THE BRIDGES AND CASE

This permits better control of the torque applied to the screws during assembly.

These screws are therefore unaffected by physical manipulation during assembly or disassembly and age well.

OTHER FEATURE

‒ Movement dimensions: 29.90 x 22.00 mm

‒ Thickness: 5.13 mm

‒ Jewels: 27

‒ Balance: CuBe, 4 arms, 4 setting weights, moment of inertia 7.5 mg•cm2, angle of lift 50°

‒ Frequency: 28,800 vph (4 Hz)

‒ Balance spring: AK3

‒ Shock protection: INCABLOC 908.22.211.100 (transparent)

CASE

The case of the RM 07-04 is made from Quartz TPT® for five watches and from Carbon TPT® for one watch.

These materials are exclusive materials to the brand in watchmaking with a unique appearance. Their remarkable damascene surface displays extremely regular yet totally unique striations, as they are composed of multiple layers of parallel filaments obtained by dividing carbon fibres or silica threads.

Quartz TPT® fibres are generally used for very high-performance applications due to their resistance to high temperatures, their strength and their transparency to electromagnetic waves. Fibres are aligned in layers no thicker than 45 microns and saturated in resins developed specially for Richard Mille. These layers are then stacked using an automatic positioning system that changes the orientation of the fibre between each layer by 45°. After being heated to 120°C and subjected to a pressure of 6 bars, they are machined on a CNC machine at Richard Mille’s manufacturing facilities.

Carbon TPT® is made by an identical process, but from carbon fibers threads.

The complete case construction is water-resistant to 50 metres thanks to two Nitrile O-rings, and is assembled with 20 spline screws in grade 5 titanium and 316L stainless steel washers.

UPPER FLANGE

In microblasted grade 5 titanium.

CRYSTAL

Bezel side

In sapphire (1,800 Vickers) with anti-glare treatment (both sides)

Thickness: 1.00 mm

Caseback

In sapphire with anti-glare treatment (both sides)

Thickness: 0.95 mm at the centre; outer edges 1.62 mm

FINISHING

MOVEMENT

- Anglage hand polished

- Microblasted milled section

- Microblasted sinks

- Black DLC treatment for the baseplate and bridges

STEEL PARTS

- Satin-finished surfaces

- Anglage hand polished

- Hand-polished bevelling

- Hand-polished locking section

PROFILE-TURNING

- Lapped and polished ends

- Burnished pivots

- Post faces polished

WHEELS

- Concave chamfering with a diamond tool

- Diamond-polished angles

- Circular-finished faces

- Rhodium plating (before cutting the teeth)

- Minimal corrections applied to the wheels in order to preserve geometry and performance