On Thursday, 7th of November, I was invited by Girard-Perregaux to visit their freshly refurbished manufacture. The Girard-Perregaux Manufacture tour was organised on three different brand’s sites. The manufacture at Rue des Crêtets, the Haute-Horlogerie Department at Rue Numa-Droz and, the final destination of the tour, the Girard-Perregaux villa. In the first part of the article, I told you about how the things are done at Rue des Crêtets, the Ulysse Nardin and Girard-Perregaux joint manufacture – where the core collection is manufactured. Today, I will present you the Haute-Horlogerie department and the brand’s vision for the future.

Girard-Perregaux Haute Horlogerie Dept.

The second part of the Girard-Perregaux Manufacture tour took place at the Haute-Horlogerie Department, situated a few streets away from the first location, at Rue Numa-Droz. Gildas Le Doussal welcomed us at the location. He is the chief of the Haute-Horlogerie division of GP.

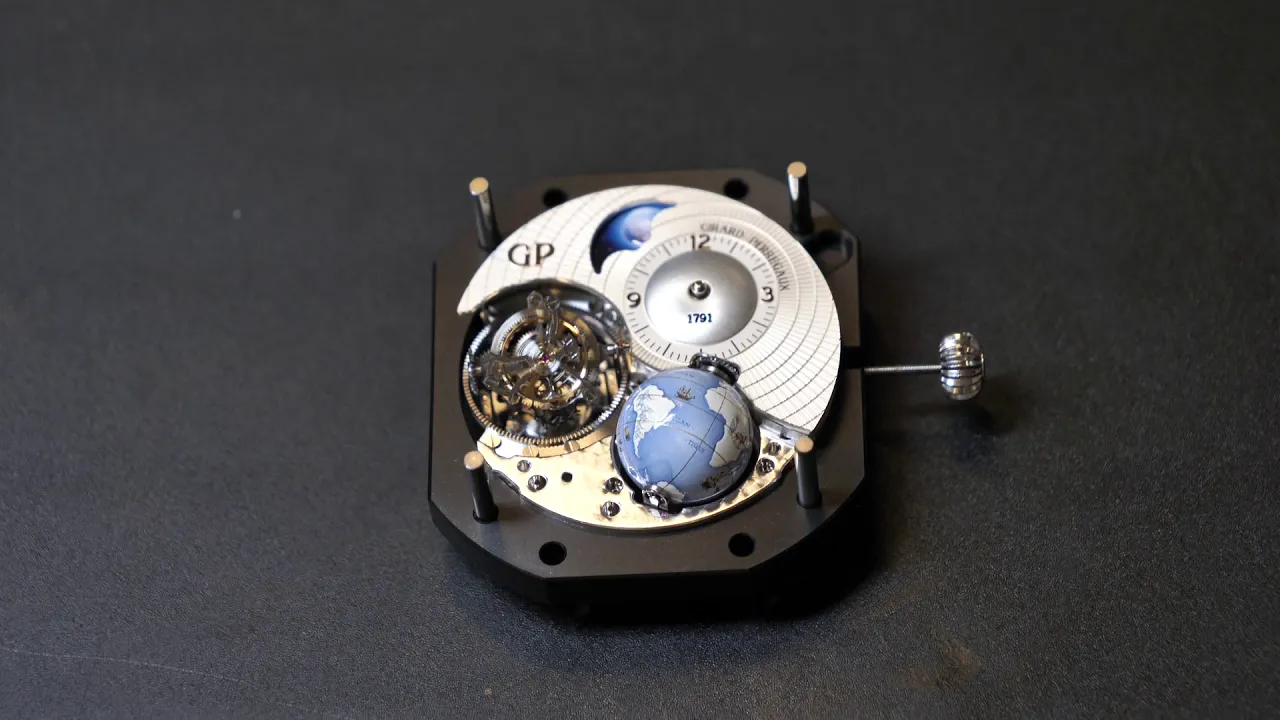

Gildas introduced us to the secrets of the hand-made watchmaking. He showed us how the Girard-Perregaux team realise the brand’s exceptional timepieces. GP has three types of watches: the core collection that is realised in the Rue des Crêtets location (check the first part of the Girard-Perregaux Manufacture tour report), the specialities (like the one he wears) and the Haute-Horlogerie (exceptional decoration – Quasar, Cosmos, Esmeralda). The last two are been taking care of at the Rue Numa-Droz facilities.

Girard-Perregaux prefers to use an external company for the coating and plating. The reason is simple – instead of investing in the equipment and be limited by its capabilities, the brand takes the advantages of specialized companies that can provide a wider and more experienced service. In this way, GP can provide to its clients a more complex set of finishes.

When OCD can be raised to the state of skill

The first room we visited was dedicated to the decorations. Six skilled watchmakers take care of the most delicate finishes. Everything here is done by hand.

Gildas explained how complex the finishing process is. The Haute-Horlogerie rigours require that any surfaces to be decorated (any surface that has been machined/CNC-ed must be hand decorated).

For the first time visible, Girard-Perregaux works with white gold GP Bridges.

One of the things that some might not understand is that: to obtain a certain look, a component must be worked by hand. As shown in the previous article, you can do many things in an automatic or semi-automatic manner, but to ensure the best quality, you need the final human touch. Working days and days for a single component, to obtain that perfect look is much harder than one might imagine.

To have an idea, to decorate a set of GP bridges, the Girard-Perregaux watchmakers need one week. At the assembling, the bridges are completed with the pins and the stones. They are ready to be mounted in the calibre after one more additional day.

Example of a bridge polishing

The polishing of the bridges, the bevelling or any other decoration that we adore, requires skilfull people and time. Lot of it. How much time can I do such a monotone operation? – Maybe half an hour. What would be the result? – Not even slightly visible. Chapeau to the women and men that can do that. These are skills that are harder and harder to find.

But please, do try this at home: take a piece of wood and a piece of metal and taste how much time you need until you leave a mark. Here in the video, you can observe how that fabulous polish is obtained.

Tooling and assembling

Girard-Perregaux has dedicated technicians and toolmakers to create and maintain the objects and tools that the finishes watchmakers need. Some of the tools are created particularly for a special operation (for instance, the hand-held holder of the bridge polished above and the Girard-Perregaux bridges support). In the premises, some fo the watchmakers use microscopes, some loupes. The final control is alway made under the microscope.

The same room has a dedicated working station for assembly special cases. For instance, this gorgeous case of a hand-engraved watch.

The assembling Atelier

In the Asamblage Atelier (assembly) work 20 watchmakers. Two watchmakers are dedicated for the after-sale service. Another two are taking care of the prototypes for the Haute-Horlogerie pieces. For the minute repeaters are dedicated four watchmakers.

As a particularity of the Haute-Horlogerie Department, the movement assembly is done from start by one watchmaker. For GP is very important to keep the traditional watchmaking skills and know-how. It is not important to speed up the process, to industrialise it, but to keep it as traditionally as possible. Also, the use of complex modern tools is completely avoided.

Usually, a HH movement has approximatively 300 components. A minute repeater can have more than 700 parts. The watchmakers assemble the movement and after a meticulous control is cased.

Some high complexity calibres (tourbillons) are assembled one time and tested. Then is disassembled, the components are cleaned and after that assembled back. The watch is tested chronometrical and aesthetical.

Girard-Perregaux also is customising pieces. The watchmakers meet with the client and discuss what and how it will be personalised.

From sapphire top to a complete sapphire case

The Quasar watch requires more care as the usual metal-cased watches. Montage needs extra care. The dust is a critical topic. After the watch is assembled, it is placed two days in a device called “the helicopter”. This will make the dust fall. The watch is cleaned again before delivery.

Intermezzo: the polishing is not over

The watchmaker polish the screws himself. These need to be perfect before montage. A watchmaker can spend up to one day to polish the screws for a movement.

Back to mounted calibres

During the assembly phase, the movements are tested always for correct functionality.

Completed watches

I got the chance to see the completed watches.

A vision into the future

The last part of my Girard-Perregaux Manufacture tour was made at the historic Girard-Perregaux villa. Anna Lundstrom (CMO) and Patrick Pruniaux (CEO) talked about the brand’s history, about the present and GP’s future.

Anna talked about the brand’s watches, that are incontestable ownable, iconic, authentic, and most of all, meaningful about Girard-Perregaux.

In the search for the purest Girard-Perregaux symbol, “We came to the bridge. We thought that is something really and truly ownable to Girard-Perregaux“, she continues, “ As the brand has for 150 years taken a technical element of the movement and transformed it into something visible into the design. So we actually took the bridge and evolved our brand language and introduced it into our branding”. – Anna Lundstrom (CMO)

A new logo

“The bridge is not just a graphic symbol for Girard-Perregaux, it is also a way to symbolise the intention to bridge between the past and the future. It further represents the link between technical mastery and iconic design, or the bridge between functionality and aesthetics. The bridges also make the link between the traditional craft of GP but also the innovation that constantly pushes forward.”, Anna concluded: “The name itself, of the brand, is born from a union – the marriage between Constant Girard and Marie Perregaux. And I believe it is the only watch brand that was born from a love story.”

Pushing the limits further

The new key attributes for Girad-Perregaux: Audacity – the courage and the vision to take a functional component of the movement and transformed it into a brand language and character; Creativity – continually reinvent the iconic design; A confident voice in the Swiss watchmaking industry; Playfulness – luxury should bring joy; Approachable – creating a community around the brand and bringing the collectors more close to the brand (that includes organising collectors visit at the GP Manufacture).

Patrick Pruniaux said: “We need to take the brand to another level. So what will come in the next months will be something interesting and defining for the brand”. He talked about the importance of places and people, referring to the newly refurbished manufacture and what comes to be next built and the importance of the excellent team of watchmakers. He considers the two as an important key to the brand’s evolution.

The future of the collections

Girard-Perregaux intends to bring the new vision towards the collections – two key pillars: the Bridges (with some new pieces coming next spring) and the Laureato (with the SIHH released Absolute and some new novelties to come). The brand is currently experimenting with carbon and sapphire, so we can expect to see something in this direction.

The 1966 and the Cat’s Eye still remain very important for the brand but the Bridges and Laureato will be extensively pushed further.

Final words

I did enjoy the Girard-Perregaux Manufacture tour. I can tell that they prepared well for this. Not in the idea to cosmetize or hide something under a nice and shiny polish. But in the idea to show that the brand is involving and evolving. That they are working hard to involve in the future of Swiss watchmaking and to evolve as a brand.

I saw happy people, I saw enthusiasm. Some things can be hidden under a smile but the expertise and experience were clearly visible. I saw people at Girad-Perregaux taking big pride of what they are doing and how they are doing it. This is indeed a key to the brand’s future success.

A big thank you to the entire Girard-Perregaux team for organising this complete Girard-Perregaux Manufacture tour. I have truly appreciated your efforts. Good luck and success with the “new” direction.

Girard-Perregaux Manufacture tour images